The unprecedented demand on solar panels, either to build Solar Farms or for Home/Business installations, created a huge parallel supply shortage of these panels worldwide. Till now, the local production of these panels in the Middle East and Africa is very limited and doesn’t cover even 1% of the market needs.

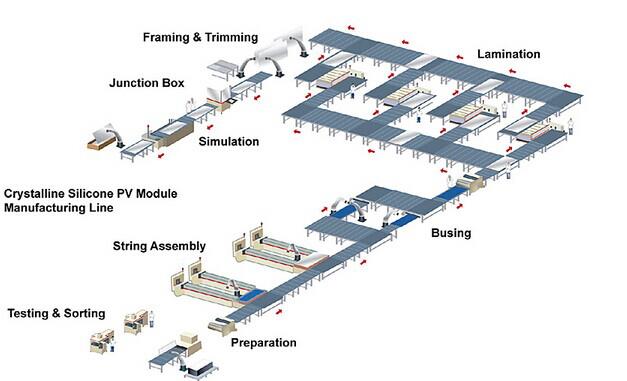

The Solar Panel manufacturing is a two steps procedure. First step is the manufacturing of the Solar Cells (in sheets) and the second step is the assembly of these Solar Sheets into Solar Panels. The First step is Technology Sensitive and may change every time a new technology emerges. The second Step is Technology Tolerant and thus is a fairly stable procedure.

200MW – 300MW ASSEMBLY LINES

ARE VERY COMMON AND TEND TO YIELD VERY HEALTHY ROI IN BOTH

3-SHIFT AND 2-SHIFT WORK SCHEDULE.

FES, through its partners, can Design, Build, Finance, Operate, Manage and Maintain Semi and Fully Automated Solar Assembly Lines at any capacity.